For a full list of publications please visit:

Sustainable electronic textiles towards scalable commercialization

HaoTian Harvey Shi, Yifei Pan, Lin Xu, Xueming Feng, Wenyu Wang, Prasad Potluri, Liangbing Hu, Tawfique Hasan & Yan Yan Shery Huang

Nature Materials, 2023, https://doi.org/10.1038/s41563-023-01615-z

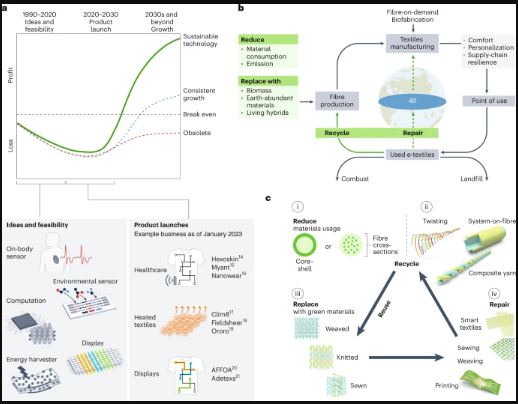

Textiles represent a fundamental material format that is extensively integrated into our everyday lives. The quest for more versatile and body-compatible wearable electronics has led to the rise of electronic textiles (e-textiles). By enhancing textiles with electronic functionalities, e-textiles define a new frontier of wearable platforms for human augmentation. To realize the transformational impact of wearable e-textiles, materials innovations can pave the way for effective user adoption and the creation of a sustainable circular economy. We propose a repair, recycle, replacement and reduction circular e-textile paradigm. We envisage a systematic design framework embodying material selection and biofabrication concepts that can unify environmental friendliness, market viability, supply-chain resilience and user experience quality. This framework establishes a set of actionable principles for the industrialization and commercialization of future sustainable e-textile products.

3D printed biomimetic cochleae and machine learning co-modelling provides clinical informatics for cochlear implant patients

Lei, IM and Jiang, C and Lei, CL and Rosalie de Rijk, S and Tam, YC and Swords, C and Sutcliffe, MPF and Malliaras, GG and Bance, M and Huang, YYS.

Nature Communications, 2021, vol 12. https://doi.org/10.1038/s41467-021-26491-6

Cochlear implants (CIs) have transformed hundreds of thousands of lives of those who suffer from severe or profound hearing loss. ‘Current spread’ hampers the efficacy of CI neuromodulation, while existing animal, in vitro and in silico models have failed to give patient-centric insights. Here we integrate 3D printing and machine learning to advance clinical predictions of current spread for cochlear implant patients. We interpreted clinical data for over 100 patients; and for the first time, extrapolated the range of patient cochlear tissue resistivity.

Link to an outreach video on Youtube

Inflight fiber printing toward array and 3D optoelectronic and sensing architectures

Wang, W and Ouaras, K and Rutz, AL and Li, X and Gerigk, M and Naegele, TE and Malliaras, GG and Huang, YYS.

Science Advances, 2020, vol. 6, no. 40. https://doi.org/10.1126/sciadv.aba0931

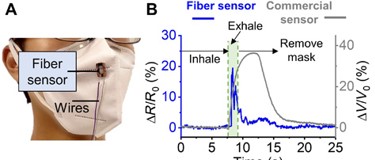

Scalability and device integration have been prevailing issues limiting our ability in harnessing the potential of small-diameter conducting fibers. We report inflight fiber printing (iFP), a one-step process that integrates conducting fiber production and fiber-to-circuit connection. Inorganic (silver) or organic {PEDOT:PSS [poly(3,4-ethylenedioxythiophene) polystyrene sulfonate]} fibers with 1- to 3-μm diameters are fabricated, with the fiber arrays exhibiting more than 95% transmittance (350 to 750 nm). The high surface area–to–volume ratio, permissiveness, and transparency of the fiber arrays were exploited to construct sensing and optoelectronic architectures. We show the PEDOT:PSS fibers as a cell-interfaced impedimetric sensor, a three-dimensional (3D) moisture flow sensor, and noncontact, wearable/portable respiratory sensors. The capability to design suspended fibers, networks of homo cross-junctions and hetero cross-junctions, and coupling iFP fibers with 3D-printed parts paves the way to additive manufacturing of fiber-based 3D devices with multilatitude functions and superior spatiotemporal resolution, beyond conventional film-based device architectures.

Multi‐Tissue Organoid Engineering: Bio‐assembling Macro‐Scale, Lumenized Airway Tubes of Defined Shape via Multi‐Organoid Patterning and Fusion (Adv. Sci. 9/2021)

Liu, Y and Dabrowska, C and Mavousian, A and Strauss, B and Meng, F and Mazzaglia, C and Ouaras, K and Macintosh, C and Terentjev, E and Lee, JH and Huang, YYS

Advanced Science, 2021, vol. 9, no. 8. https://doi.org/10.1002/advs.202170046

A robust organoid engineering method is developed to ‘up‐size’ and ‘shape’ organoids—miniature collections of cells which mimic biological features of an organ. The method, named Multi‐Organoid Patterning and Fusion (MOrPF), is used to assemble scaffold‐free macroscale airway tubes, leading to flowable organoid‐on‐a‐chip, and branching tubular structures. The organoid fusion process is characterised by inter‐organoid surface integration, luminal clearance, and lumina connection.

Broad Bandwidth, Self-Powered Acoustic Sensor Created by Dynamic Near-Field Electrospinning of Suspended, Transparent Piezoelectric Nanofiber Mesh

Wang, W and Stipp, PN and Ouaras, K and Fathi, S and Huang, YYS.

Small, 2020, vol. 16. https://doi.org/10.1002/smll.202000581

Freely suspended nanofibers, such as spider silk, harnessing their small diameter (sub‐micrometer) and spanning fiber morphology, behave as a nonresonating acoustic sensor. The associated sensing characteristics, departing from conventional resonant acoustic sensors, could be of tremendous interest for the development of high sensitivity, broadband audible sensors for applications in environmental monitoring, biomedical diagnostics, and internet‐of‐things. Herein, a low packing density, freely suspended nanofiber mesh with a piezoelectric active polymer is fabricated, demonstrating a self‐powered acoustic sensing platform with broad sensitivity bandwidth covering 200–5000 Hz at hearing‐safe sound pressure levels. Dynamic near‐field electrospinning is developed to fabricate in situ poled poly(vinylidene fluoride‐co‐trifluoroethylene) (P(VDF‐TrFE)) nanofiber mesh (average fiber diameter ≈307 nm), exhibiting visible light transparency greater than 97%. With the ability to span the nanomesh across a suspension distance of 3 mm with minimized fiber stacking (≈18% fiber packing density), individual nanofibers can freely imitate the acoustic‐driven fluctuation of airflow in a collective manner, where piezoelectricity is harvested at two‐terminal electrodes for direct signal collection. Applications of the nanofiber mesh in music recording with good signal fidelity are demonstrated.

On-chip perivascular niche supporting stemness of patient-derived glioma cells in a serum-free, flowable culture

Gerigk, M and Bulstrode, H and Shi, HTH and Tönisen, F and Cerutti, C and Morrison, G and Rowitch, D and Huang, YYS.

Lab on a Chip, 2021, vol 21. https://doi.org/10.1039/D1LC00271F

Glioblastoma multiforme (GBM) is the most common and the most aggressive type of primary brain malignancy. Glioblastoma stem-like cells (GSCs) can migrate in vascular niches within or away from the tumour mass, increasing tumour resistance to treatments and contributing to relapses. To study individual GSC migration and their interactions with the perivasculature of the tumour microenvironment, there is a need to develop a human organotypic in vitro model. Herein, we demonstrated a perivascular niche-on-a-chip, in a serum-free condition with gravity-driven flow, that supported the stemness of patient-derived GSCs and foetal neural stem cells grown in a three-dimensional environment (3D).

Fabrication of Designable and Suspended Microfibers via Low-Voltage 3D Micropatterning

Gill, EL and Willis, S and Gerigk, M and Cohen, P and Zhang, D and Li, X and Huang, YYS.

ACS Applied Materials & Interfaces, 2019, vol. 11. https://doi.org/10.1021/acsami.9b01258

Building two-dimensional (2D) and three-dimensional (3D) fibrous structures in the micro- and nanoscale will offer exciting prospects for numerous applications spanning from sensors to energy storage and tissue engineering scaffolds. Electrospinning is a well-suited technique for drawing micro- to nanoscale fibers, but current methods of building electrospun fibers in 3D are restrictive in terms of printed height, design of macroscopic fiber networks, and choice of polymer. Here, we combine low-voltage electrospinning and additive manufacturing as a method to pattern layers of suspended mesofibers. Layers of fibers are suspended between 3D-printed supports in situ in multiple fiber layers and designable orientations. We examine the key working parameters to attain a threshold for fiber suspension, use those behavioral observations to establish a “fiber suspension indicator”, and demonstrate its utility through design of intricate suspended fiber architectures. Individual fibers produced by this method approach the micrometer/submicrometer scale, while the overall suspended 3D fiber architecture can span over a centimeter in height. We demonstrate an application of suspended fiber architectures in 3D cell culture, utilizing patterned fiber topography to guide the assembly of suspended high-cellular-density structures. The solution-based fiber suspension patterning process we report offers a unique competence in patterning soft polymers, including extracellular matrix-like materials, in a high resolution and aspect ratio. The platform could thus offer new design and manufacturing capabilities of devices and functional products by incorporating functional fibrous elements.