3D Printing Soft, Bio and Green

Fibres as building blocks & Fibre-of-Things

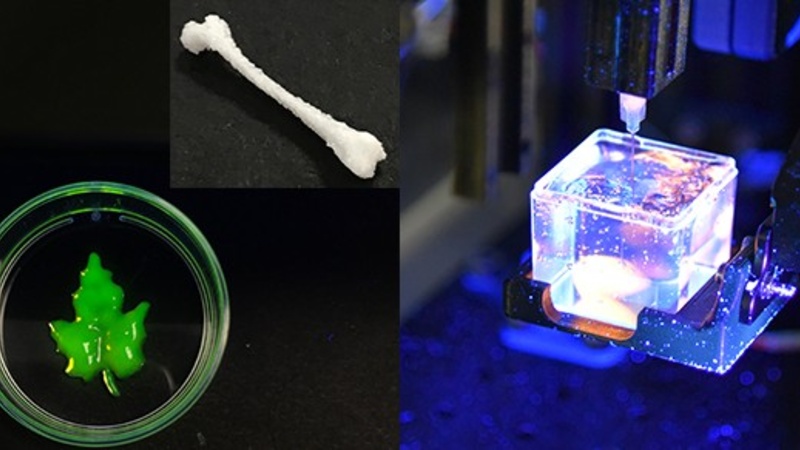

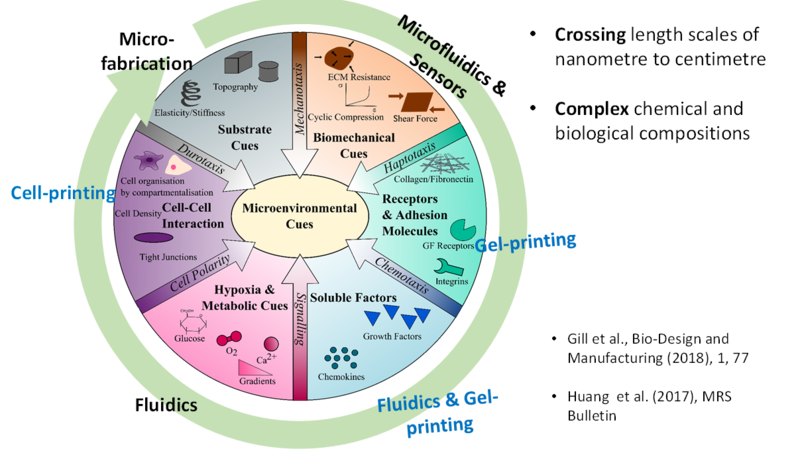

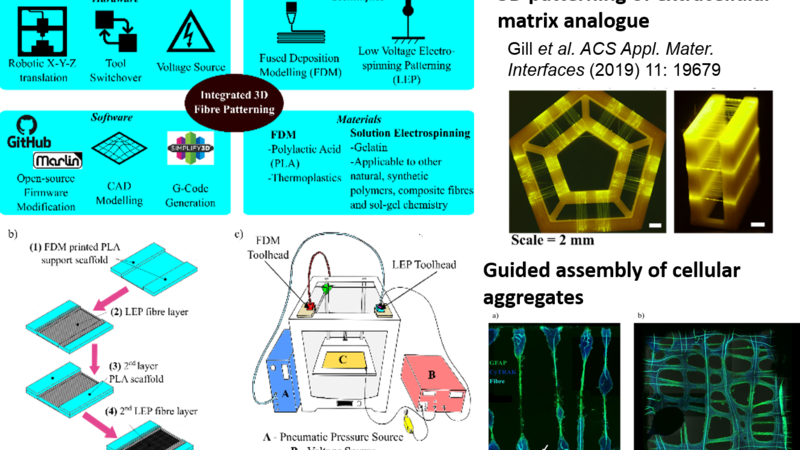

We are developing low waste, direct-write fibre technology to pattern bioactive, biocompatible fibrils, gels and sensing elements. Ultimately, the biomimetic construct will provide the building blocks for tissue regeneration. These soft electronic systems could also see a wide range of applications where electrical stimuli are required to deliver to the cellular system, a good example being the neural electrode. To realise these applications, within our lab we have demonstrated a number of novel 3D printing techniques.

https://doi.org/10.1021/acsami.9b01258

https://doi.org/10.1021/acsami.6b07797

Additive batch electrospinning

Limited methods exist to integrate patterning of free-spanning hydrogel microfibres as part of an additive manufacturing strategy. We demonstrate 3D additive batch electrospinning (3D-abES) workflow to efficiently produce layered hydrogel gelatin microfibres, tethered to 3D printed thermoplastic structures of various shapes. Enabled by the digital-design approach, multiple 3D printed fibre devices can be fabricated in a batch efficiently with minimised sample-to-sample variance. Customised fibre patterns and device geometries can be rapidly altered to fit with potential applications in 6- to 24- well plate formats.

https://doi.org/10.1016/j.addma.2020.101456