Context: The next generation step change in health treatment could harness personalised bionic implants combining biological or physical stimuli, with a patient's own cells, to replace diseased or damaged tissues and organs. There will also be development in drug research through the creation of complex tissue models in vitro that mimic certain body systems. With these models we will be able to reduce the need for animal testing and provide a deeper understanding of the impact of drugs on cell function. To undertake these changes, one requires a fabrication technique that can accommodate a wider choice of biomaterials, combined with delivery of complexity in terms of feature size, structure and functionalities.

Inflight fiber printing to construct sensing and optoelectronic architectures

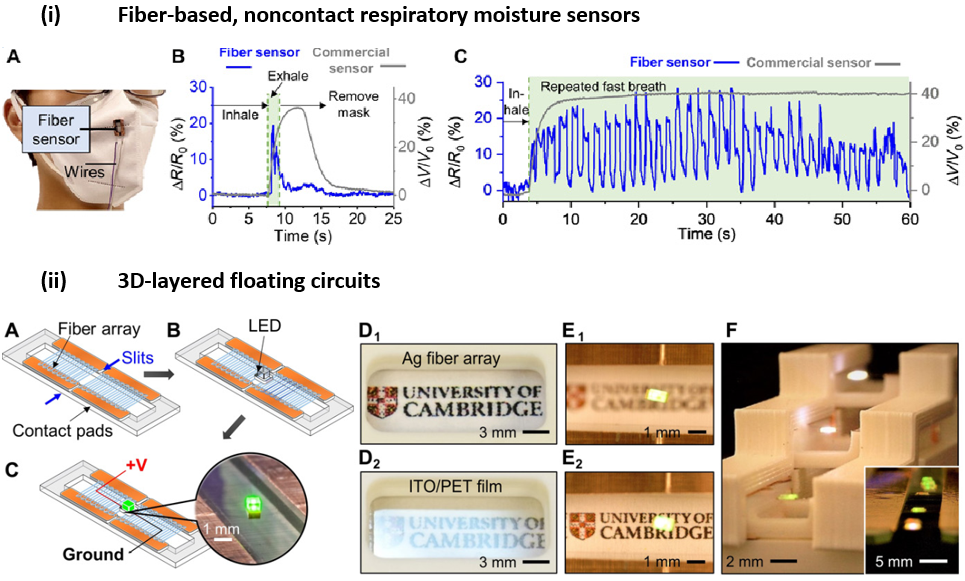

We have developed a technique known as inflight fiber printing, which is a one-step process that creates and in situ bonds thin conducting fiber arrays, either suspended or on a surface, without the need for any post-processing. This technique allows the synthesis of fiber arrays with the unique characteristics of high surface area–to–volume ratio, permissiveness, and transparency. We have demonstrated the applicability of this technique in synthesising a cell-interfaced impedimetric sensor, a three-dimensional moisture flow sensor, and noncontact, wearable/portable respiratory sensors. The novel circuitry architecture afforded by our fiber printing process has also allowed us to explore and present the concept of 3D “floating electronic architectures”.

Wenyu Wang et al. Science Advances (2020)

Bio-inspired fabrication and 3D printing

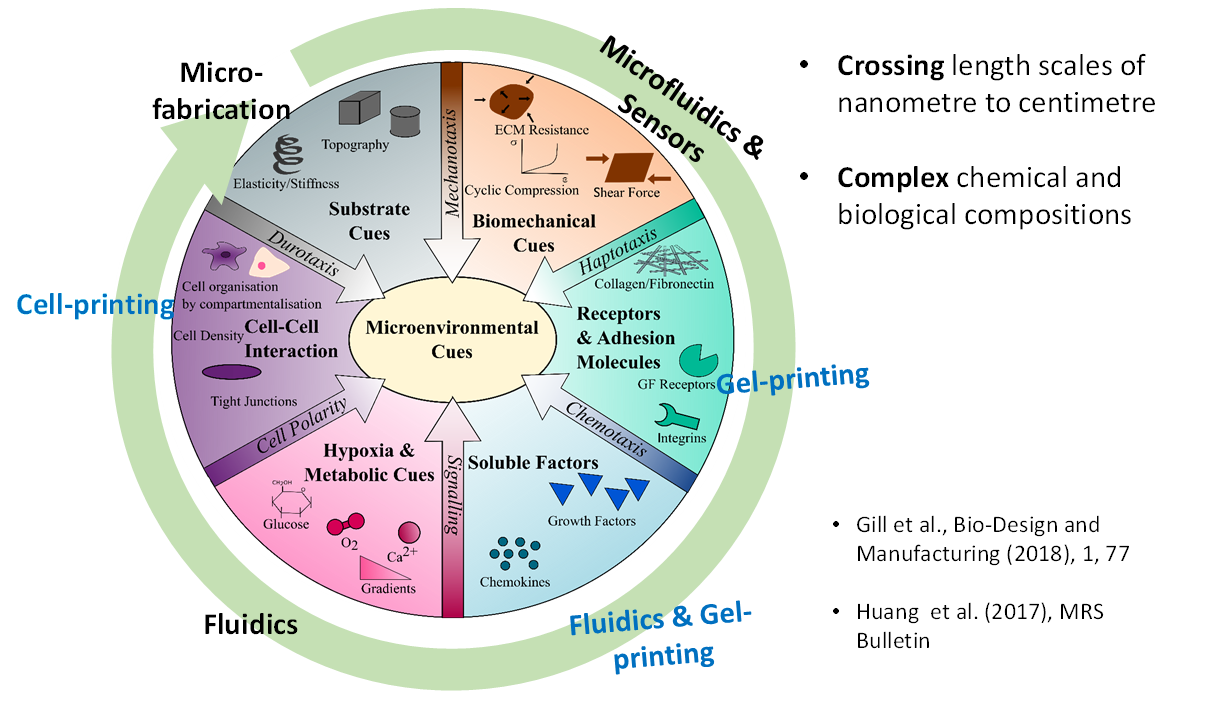

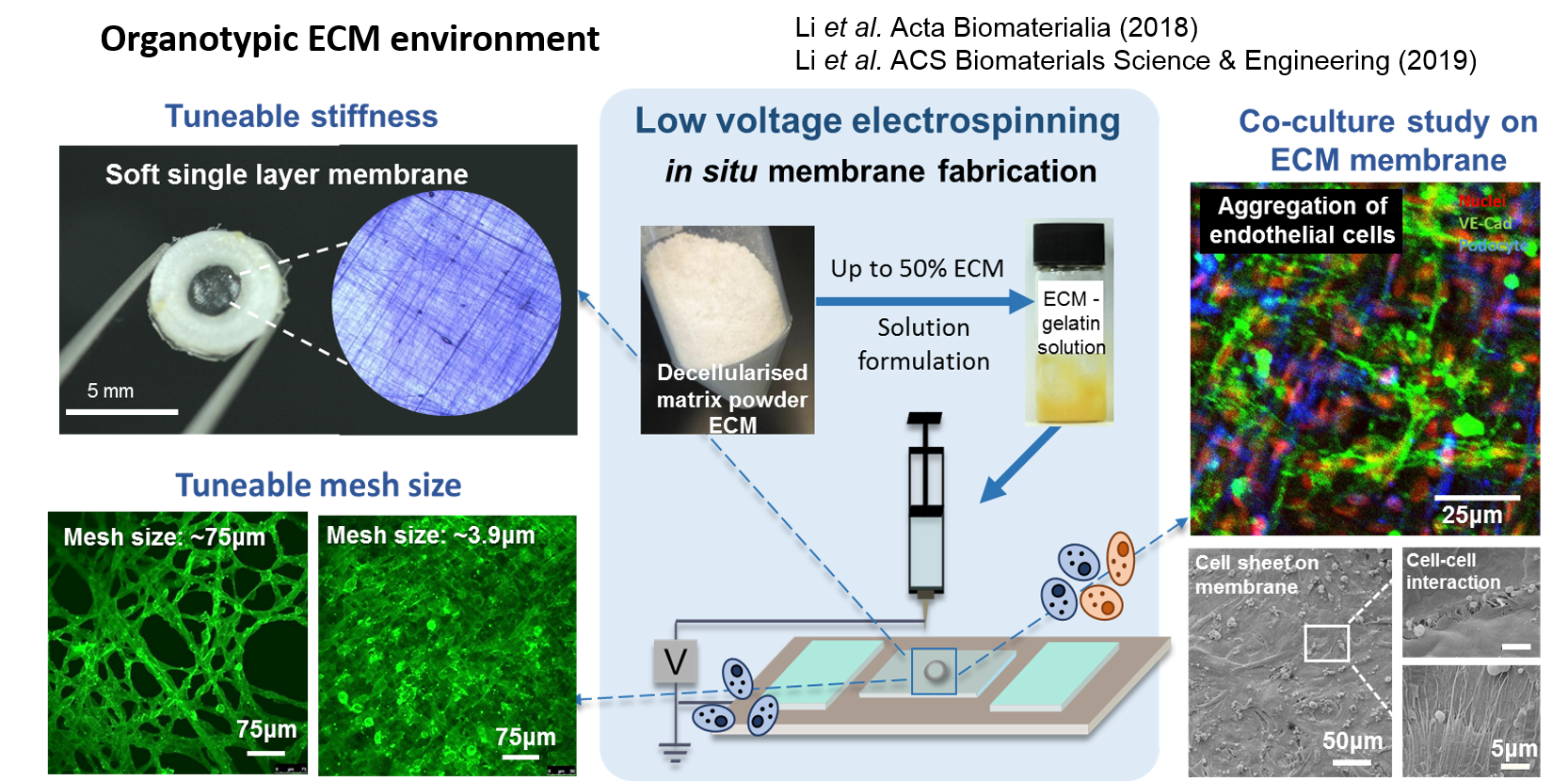

We combine nanotechology and new material fabrication techniques to construct the defined biochemical and physical inputs of an ECM scaffold. Through guided self-assembly and tissue morphogenesis, we hope to recapitulate the key attributes of a tissue 'niche'.

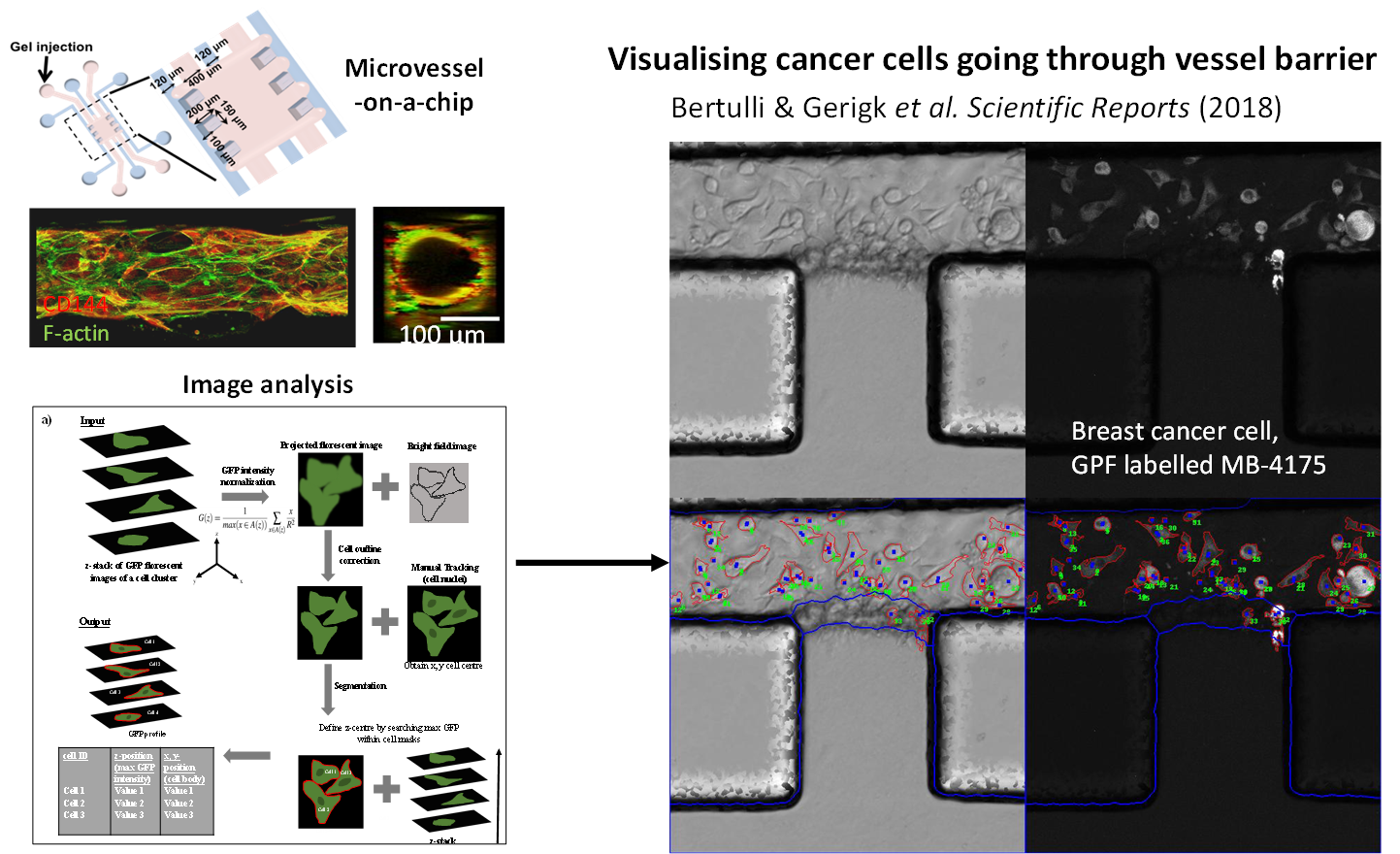

Microvessel-on-a-chip and organ-on-a-chip as pathological models

This research area focuses on developing models to recapitulate the microvasculature, and other key microenvironment factors for living cells in a fluidic device. Specifically, we apply our materials approach to study the motility of cancer cells when they interact with a vessel formed by the endothelial cells, to mimic the conditions of cancer invasion. We have also created a glomerulus-on-a-chip, for industry-relevant drug testing of kidney disease.

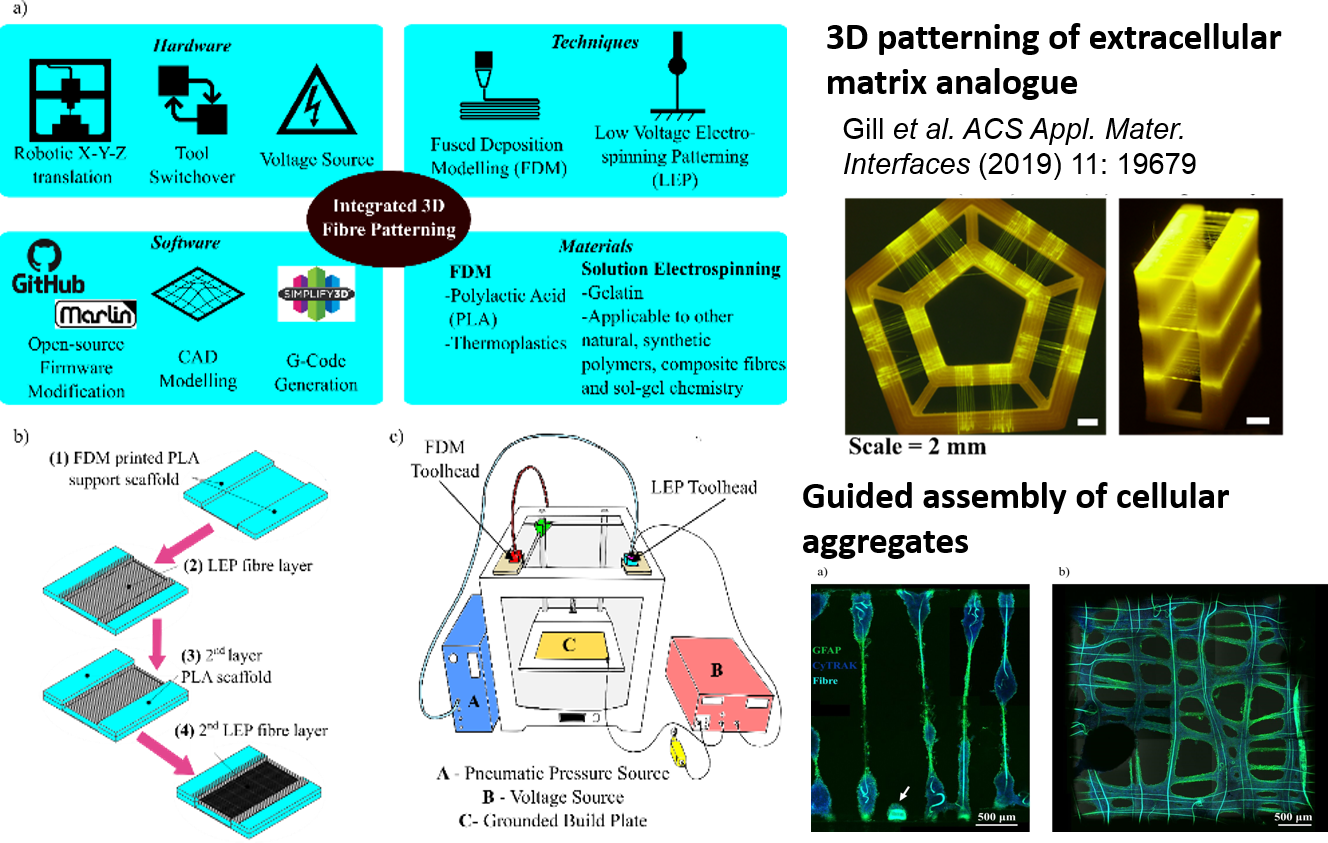

Fibre elements for cell patterning, tissue scaffolds, and bioelectronics

We are developing low waste, direct-write fibre technology to pattern bioactive, biocompatible fibrils, gels and sensing elements. Ultimately, the biomimetic construct will provide the building blocks for tissue regeneration. These soft electronic systems could also see a wide range of applications where electrical stimuli are required to deliver to the cellular system, a good example being the neural electrode. The development of this biofabrication technology will require in-depth understanding of the electrodyanmics of jet formation, precision instrumentation, and innovative materials processing.

Soft tissue engineering

Both mechanical and biochemical properties of the interfacing substrate play critical roles in the process of cell differentiation/ growth and tissue regeneration. Combining nanomaterials and new fabrication techniques, material interfaces mimicking biological tissue environments can be fabricated. The project is hoped to bring further understanding in how the change in different physical environments (such as stiffness, electrical stimuli, surface roughness and anisotropy) will affect the differentiation/ growth/ maintenance of stem cells. The results also hold the key to optimise the material microstructure for tissue engineering and bioelectronic applications.