For a full list of publications please visit:

Featured publications

Synthesizing vascular trees at speed

Yan Yan Shery Huang and Lining Arnold Ju

Science (2025) https://www.science.org/stoken/author-tokens/ST-2678/full

Biofabrication and Biomanufacturing hold immense potential to address global health challenges by significantly increasing the supply of organs and tissues for drug screening and transplantation over the next decade. Through innovative design and system-level engineering biology, which seamlessly integrates experimental and computational approaches, we are moving closer to the goal of biomanufacturing functional human tissues and organs at clinically relevant scales.

Cryopreservation of In Vitro Human Tissue Models

Yaqi Sheng, Yan Yan Shery Huang

Nature Review Bioengineering (2024) https://rdcu.be/dYEXt

In this Comment article, we propose that the widespread use and translation of engineered in vitro tissues, such as organoids, organ-on-chip devices and microphysiological models, will require designs that can be preserved by cryopreservation. Here, we outline the factors that affect their cryopreservation, highlighting the challenges that remain to be addressed.

Imperceptible augmentation of living systems with organic bioelectronic fibres

Wenyu Wang, Yifei Pan, Yuan Shui, Tawfique Hasan, Iek Man Lei, Stanley Gong Sheng Ka, Thierry Savin, Santiago Velasco-Bosom, Yang Cao, Susannah B. P. McLaren, Yuze Cao, Fengzhu Xiong, George G. Malliaras & Yan Yan Shery Huang*

Nature Electronics, 2024 https://www.nature.com/articles/s41928-024-01174-4

The functional and sensory augmentation of living structures, such as human skin and plant epidermis, with electronics can be used to create platforms for health management and environmental monitoring. Ideally, such bioelectronic interfaces should not obstruct the inherent sensations and physiological changes of their hosts. The full life cycle of the interfaces should also be designed to minimize their environmental footprint. Here we report imperceptible augmentation of living systems through in situ tethering of organic bioelectronic fibres. Using an orbital spinning technique, substrate-free and open fibre networks—which are based on poly (3,4-ethylenedioxythiophene):polystyrene sulfonate—can be tethered to biological surfaces, including fingertips, chick embryos and plants. We use customizable fibre networks to create on-skin electrodes that can record electrocardiogram and electromyography signals, skin-gated organic electrochemical transistors and augmented touch and plant interfaces. We also show that the fibres can be used to couple prefabricated microelectronics and electronic textiles, and that the fibres can be repaired, upgraded and recycled.

Featured in Nature Electronics News and Views: Building bioelectronic fibres with a light touch

Also see video summary Sensors made from 'electronic spider silks' directly printed on skin

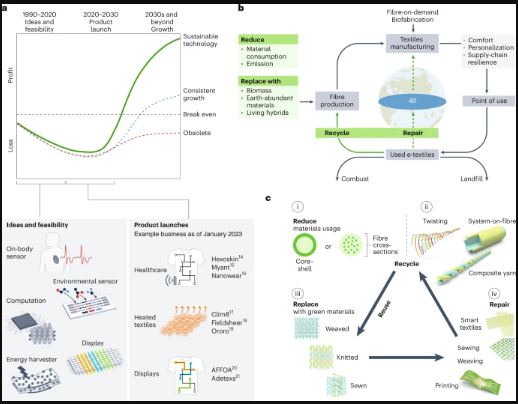

Sustainable electronic textiles towards scalable commercialization

HaoTian Harvey Shi, Yifei Pan, Lin Xu, Xueming Feng, Wenyu Wang, Prasad Potluri, Liangbing Hu, Tawfique Hasan & Yan Yan Shery Huang

Nature Materials, 2023, https://doi.org/10.1038/s41563-023-01615-z

Textiles represent a fundamental material format that is extensively integrated into our everyday lives. The quest for more versatile and body-compatible wearable electronics has led to the rise of electronic textiles (e-textiles). By enhancing textiles with electronic functionalities, e-textiles define a new frontier of wearable platforms for human augmentation. To realize the transformational impact of wearable e-textiles, materials innovations can pave the way for effective user adoption and the creation of a sustainable circular economy. We propose a repair, recycle, replacement and reduction circular e-textile paradigm. We envisage a systematic design framework embodying material selection and biofabrication concepts that can unify environmental friendliness, market viability, supply-chain resilience and user experience quality. This framework establishes a set of actionable principles for the industrialization and commercialization of future sustainable e-textile products.

3D printed biomimetic cochleae and machine learning co-modelling provides clinical informatics for cochlear implant patients

Lei, IM and Jiang, C and Lei, CL and Rosalie de Rijk, S and Tam, YC and Swords, C and Sutcliffe, MPF and Malliaras, GG and Bance, M and Huang, YYS.

Nature Communications, 2021, vol 12. https://doi.org/10.1038/s41467-021-26491-6

Cochlear implants (CIs) have transformed hundreds of thousands of lives of those who suffer from severe or profound hearing loss. ‘Current spread’ hampers the efficacy of CI neuromodulation, while existing animal, in vitro and in silico models have failed to give patient-centric insights. Here we integrate 3D printing and machine learning to advance clinical predictions of current spread for cochlear implant patients. We interpreted clinical data for over 100 patients; and for the first time, extrapolated the range of patient cochlear tissue resistivity.

Link to an outreach video on Youtube

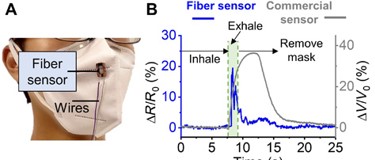

Inflight fiber printing toward array and 3D optoelectronic and sensing architectures

Wang, W and Ouaras, K and Rutz, AL and Li, X and Gerigk, M and Naegele, TE and Malliaras, GG and Huang, YYS.

Science Advances, 2020, vol. 6, no. 40. https://doi.org/10.1126/sciadv.aba0931

Scalability and device integration have been prevailing issues limiting our ability in harnessing the potential of small-diameter conducting fibers. We report inflight fiber printing (iFP), a one-step process that integrates conducting fiber production and fiber-to-circuit connection. Inorganic (silver) or organic {PEDOT:PSS [poly(3,4-ethylenedioxythiophene) polystyrene sulfonate]} fibers with 1- to 3-μm diameters are fabricated, with the fiber arrays exhibiting more than 95% transmittance (350 to 750 nm). The high surface area–to–volume ratio, permissiveness, and transparency of the fiber arrays were exploited to construct sensing and optoelectronic architectures. We show the PEDOT:PSS fibers as a cell-interfaced impedimetric sensor, a three-dimensional (3D) moisture flow sensor, and noncontact, wearable/portable respiratory sensors. The capability to design suspended fibers, networks of homo cross-junctions and hetero cross-junctions, and coupling iFP fibers with 3D-printed parts paves the way to additive manufacturing of fiber-based 3D devices with multilatitude functions and superior spatiotemporal resolution, beyond conventional film-based device architectures.

Multi‐Tissue Organoid Engineering: Bio‐assembling Macro‐Scale, Lumenized Airway Tubes of Defined Shape via Multi‐Organoid Patterning and Fusion (Adv. Sci. 9/2021)

Liu, Y and Dabrowska, C and Mavousian, A and Strauss, B and Meng, F and Mazzaglia, C and Ouaras, K and Macintosh, C and Terentjev, E and Lee, JH and Huang, YYS

Advanced Science, 2021, vol. 9, no. 8. https://doi.org/10.1002/advs.202170046

A robust organoid engineering method is developed to ‘up‐size’ and ‘shape’ organoids—miniature collections of cells which mimic biological features of an organ. The method, named Multi‐Organoid Patterning and Fusion (MOrPF), is used to assemble scaffold‐free macroscale airway tubes, leading to flowable organoid‐on‐a‐chip, and branching tubular structures. The organoid fusion process is characterised by inter‐organoid surface integration, luminal clearance, and lumina connection.

On-chip perivascular niche supporting stemness of patient-derived glioma cells in a serum-free, flowable culture

Gerigk, M and Bulstrode, H and Shi, HTH and Tönisen, F and Cerutti, C and Morrison, G and Rowitch, D and Huang, YYS.

Lab on a Chip, 2021, vol 21. https://doi.org/10.1039/D1LC00271F

Glioblastoma multiforme (GBM) is the most common and the most aggressive type of primary brain malignancy. Glioblastoma stem-like cells (GSCs) can migrate in vascular niches within or away from the tumour mass, increasing tumour resistance to treatments and contributing to relapses. To study individual GSC migration and their interactions with the perivasculature of the tumour microenvironment, there is a need to develop a human organotypic in vitro model. Herein, we demonstrated a perivascular niche-on-a-chip, in a serum-free condition with gravity-driven flow, that supported the stemness of patient-derived GSCs and foetal neural stem cells grown in a three-dimensional environment (3D).

Biofabrication and biomanufacturing in Ireland and the UK

Bio-Design and Manufacturing (2024); Link to publication: https://link.springer.com/article/10.1007/s42242-024-00316-z

As we navigate the transition from the Fourth to the Fifth Industrial Revolution, the emerging fields of biomanufacturing and biofabrication are transforming life sciences and healthcare. These sectors are benefiting from a synergy of synthetic and engineering biology, sustainable manufacturing, and integrated design principles. Advanced techniques such as 3D bioprinting, tissue engineering, directed assembly, and self-assembly are instrumental in creating biomimetic scaffolds, tissues, organoids, medical devices, and biohybrid systems. The field of biofabrication in the United Kingdom and Ireland is emerging as a pivotal force in bioscience and healthcare, propelled by cutting-edge research and development. Concentrating on the production of biologically functional products for use in drug delivery, in vitro models, and tissue engineering, research institutions across these regions are dedicated to innovating healthcare solutions that adhere to ethical standards while prioritising sustainability, affordability, and healthcare system benefits.